The Silent Energy Drain: Why Manufacturing Needs an AI Intervention

Manufacturing, the backbone of economies, often operates as a colossal energy glutton. We’re not talking about turning off lights at the end of the day. This is about deeply embedded inefficiencies, hidden in complex processes, that silently bleed profits and contribute to a hefty carbon footprint. Imagine your factory floor as a living organism, every machine a vital organ, consuming energy to function. But what if some organs are working harder than they need to, wasting precious resources? That’s the problem.

For years, manufacturers have relied on traditional methods – audits, manual adjustments, and reactive maintenance – to manage energy consumption. These methods, while valuable, are often like trying to bail out a sinking ship with a teaspoon. They’re slow, incomplete, and lack the real-time adaptability needed to truly optimize energy usage in a dynamic environment.

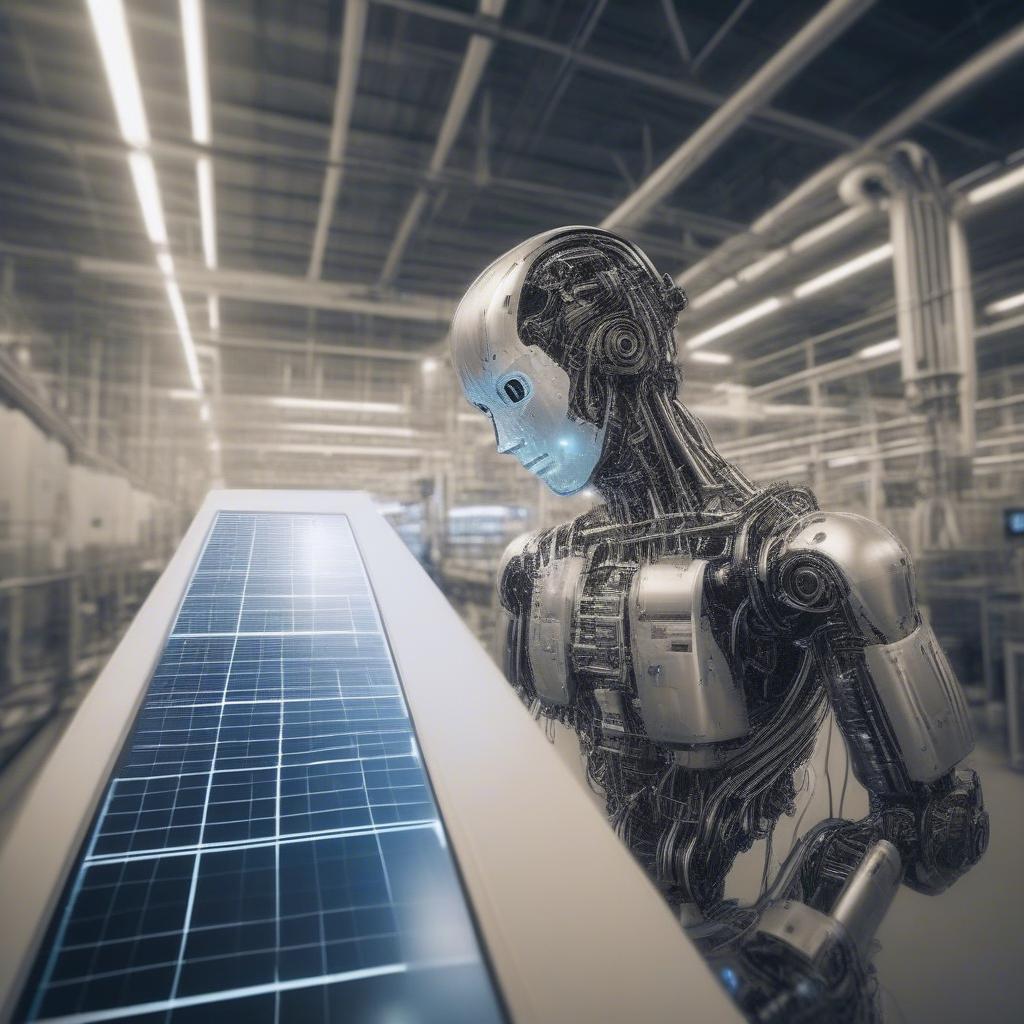

Enter Artificial Intelligence (AI). No longer just a futuristic buzzword, AI is transforming manufacturing, offering a powerful solution to slash energy costs and drive sustainable practices. Think of AI as a super-smart energy detective, constantly monitoring every nook and cranny of your operation, identifying waste, and suggesting optimal strategies.

But how does AI actually do this? And what kind of savings are we talking about? Let’s dive in.

Decoding AI’s Energy-Saving Magic: What, How, and Why Now?

At its core, AI’s ability to reduce energy costs hinges on its superior analytical power. It’s about processing massive datasets, identifying patterns invisible to the human eye, and predicting future energy needs with astonishing accuracy. Forget gut feelings and educated guesses; AI delivers data-driven insights that can revolutionize your energy management strategy.

What exactly can AI do?

- Real-time Monitoring and Optimization: AI algorithms continuously track energy consumption across all areas of the plant, from individual machines to entire production lines. This allows for immediate adjustments to operating parameters, ensuring that energy is used only when and where it’s needed. Think of it like a smart thermostat for your entire factory, constantly tweaking settings for maximum efficiency.

- Predictive Maintenance: Machine breakdowns are a major energy drain. A failing motor, for example, can draw significantly more power than a healthy one. AI-powered predictive maintenance systems analyze sensor data (vibration, temperature, sound) to identify potential failures before they occur. This allows for proactive repairs, preventing costly downtime, wasted energy, and potential safety hazards. Imagine diagnosing a heart condition before it leads to a heart attack – that’s the power of predictive maintenance.

- Demand Forecasting and Scheduling: Manufacturing demand fluctuates, leading to periods of high and low energy consumption. AI algorithms can analyze historical data, market trends, and even weather patterns to accurately forecast future demand. This allows for optimized production scheduling, minimizing idle time and reducing energy waste. It’s like having a crystal ball that lets you plan your production schedule perfectly, minimizing energy peaks and valleys.

- Process Optimization: Many manufacturing processes are inherently inefficient. AI can analyze these processes, identify bottlenecks, and suggest improvements that reduce energy consumption without compromising product quality. This could involve optimizing machine speeds, adjusting temperature settings, or streamlining workflows. It’s about fine-tuning every aspect of your operation to squeeze out every last drop of energy efficiency.

- Smart Grid Integration: As more manufacturers connect to smart grids, AI can play a crucial role in optimizing energy consumption based on real-time grid conditions. This allows companies to take advantage of lower energy prices during off-peak hours and reduce their reliance on fossil fuels. It’s about becoming a responsible energy citizen, contributing to a more sustainable and resilient grid.

How does AI achieve these feats?

The magic lies in a combination of machine learning techniques:

- Supervised Learning: AI algorithms are trained on historical data (e.g., energy consumption, production output, machine sensor readings) to learn the relationship between different variables. This allows them to predict future energy needs and identify potential inefficiencies.

- Unsupervised Learning: AI algorithms analyze data without prior training to identify hidden patterns and anomalies. This can help uncover unexpected sources of energy waste and provide insights into areas that need further investigation.

- Reinforcement Learning: AI algorithms learn through trial and error, optimizing energy consumption by continuously adjusting operating parameters based on feedback. This is particularly useful for complex processes where the optimal solution is not immediately obvious.

Why is AI so crucial right now?

The convergence of several factors makes AI adoption for energy efficiency in manufacturing more urgent than ever:

- Rising Energy Costs: Fluctuating energy prices are putting immense pressure on manufacturers’ bottom lines. AI offers a powerful tool to mitigate these costs and maintain profitability.

- Increased Environmental Regulations: Governments worldwide are tightening environmental regulations, forcing manufacturers to reduce their carbon footprint. AI can help companies comply with these regulations and avoid costly penalties.

- Growing Consumer Demand for Sustainability: Consumers are increasingly demanding environmentally friendly products and practices. Manufacturers that embrace sustainability can gain a competitive advantage and attract environmentally conscious customers.

- Advancements in AI Technology: AI technology is rapidly evolving, becoming more accessible, affordable, and user-friendly. This makes it easier for manufacturers of all sizes to implement AI solutions and reap the benefits.

A 2024 Case Study: The Acme Steel Transformation

Let’s move from theory to reality. Acme Steel, a medium-sized steel manufacturer, provides a compelling example of how AI can dramatically reduce energy costs. Acme, like many steel producers, faced mounting pressure to cut energy consumption and reduce its environmental impact. They were struggling with outdated equipment, inefficient processes, and a lack of real-time data insights.

The Challenge:

- High energy bills, impacting profitability.

- Difficulty meeting increasingly stringent environmental regulations.

- Inability to identify and address hidden sources of energy waste.

- Reactive maintenance approach leading to costly downtime and energy spikes.

The Solution: Implementing an AI-Powered Energy Management System

Acme Steel partnered with an AI solutions provider to implement a comprehensive energy management system. This system involved:

- Installing sensors: Sensors were deployed throughout the plant to collect real-time data on energy consumption, machine performance, temperature, and other relevant parameters.

- Implementing AI algorithms: The collected data was fed into AI algorithms that were trained to identify patterns, predict future energy needs, and optimize operating parameters.

- Integrating with existing systems: The AI system was integrated with Acme’s existing manufacturing execution system (MES) and enterprise resource planning (ERP) system to ensure seamless data flow and coordinated decision-making.

Specific AI Applications:

- Predictive Maintenance: AI algorithms analyzed sensor data to predict potential equipment failures. This allowed Acme to proactively repair or replace failing equipment, preventing costly downtime and energy spikes. For example, AI identified a failing motor in a rolling mill weeks before it would have broken down, preventing a major disruption and saving an estimated $50,000 in repair costs and lost production.

- Process Optimization: AI analyzed the steelmaking process, identifying inefficiencies in the heating and cooling cycles. The AI system suggested adjustments to temperature settings and heating durations, resulting in a significant reduction in energy consumption. They used machine learning to optimize the temperature control in their annealing furnaces, reducing gas consumption by 15% without affecting steel quality.

- Demand Forecasting and Scheduling: AI algorithms analyzed historical sales data and market trends to accurately forecast future demand. This allowed Acme to optimize production scheduling, minimizing idle time and reducing energy waste. The AI system helped them predict demand fluctuations with 90% accuracy, enabling them to optimize their production schedule and reduce energy consumption during off-peak periods.

- Smart Grid Integration: Acme integrated its AI system with the local smart grid, allowing it to take advantage of lower energy prices during off-peak hours and reduce its reliance on fossil fuels. They automated the shifting of energy-intensive tasks to off-peak hours, saving them another 10% on their electricity bill.

The Results:

- 20% reduction in overall energy consumption. This translated into significant cost savings, boosting Acme’s bottom line.

- 15% reduction in carbon emissions. Acme significantly reduced its environmental impact and improved its sustainability profile.

- Improved equipment reliability and reduced downtime. Predictive maintenance allowed Acme to proactively address potential equipment failures, minimizing disruptions and improving overall productivity.

- Enhanced decision-making. Real-time data insights provided managers with the information they needed to make informed decisions about energy management and production scheduling.

- Payback period of less than 18 months. The investment in the AI system paid for itself in less than two years, demonstrating the significant return on investment.

Key Takeaways from the Acme Steel Case Study:

- AI can deliver significant energy savings in manufacturing, even in traditionally energy-intensive industries like steel production.

- A comprehensive AI solution that integrates with existing systems is crucial for maximizing results.

- Predictive maintenance is a powerful application of AI that can prevent costly downtime and energy spikes.

- Data-driven insights empower managers to make informed decisions about energy management and production scheduling.

- The return on investment for AI-powered energy management systems can be substantial.

Getting Started: A Practical Guide to AI Implementation for Energy Efficiency

Okay, so you’re convinced that AI can help you cut energy costs. But where do you begin? Implementing AI can seem daunting, but with a structured approach, it’s entirely achievable. Here’s a step-by-step guide:

Step 1: Assess Your Current Energy Landscape

- Conduct a thorough energy audit: Identify your biggest energy consumers and areas where energy is being wasted. This is your baseline. Use tools like thermal imaging to spot heat losses, and power quality analyzers to detect inefficiencies in electrical systems.

- Collect data: Gather historical data on energy consumption, production output, machine performance, and other relevant parameters. The more data you have, the better the AI can learn.

- Identify your biggest pain points: What are your biggest energy-related challenges? Is it downtime due to equipment failures? Inefficient processes? High peak demand charges?

Step 2: Define Your Goals and Objectives

- Set specific, measurable, achievable, relevant, and time-bound (SMART) goals: For example, “Reduce overall energy consumption by 15% within the next 12 months.”

- Prioritize your objectives: Focus on the areas where AI can have the biggest impact.

- Develop a clear roadmap: Outline the steps you will take to achieve your goals.

Step 3: Choose the Right AI Solution

- Research different AI solutions: There are a variety of AI solutions available for energy management, each with its own strengths and weaknesses. Consider the specific needs of your operation and choose a solution that is tailored to your requirements.

- Evaluate vendors: Compare different vendors based on their experience, expertise, and track record. Look for vendors with experience in your specific industry.

- Consider cloud-based solutions: Cloud-based AI solutions can be more cost-effective and easier to implement than on-premise solutions.

Step 4: Pilot Project and Proof of Concept

- Start small: Implement the AI solution in a pilot project to test its effectiveness and identify any potential issues.

- Focus on a specific area: Choose a specific area of your plant or a particular process to focus on.

- Monitor results closely: Track energy consumption and other relevant metrics to measure the impact of the AI solution.

Step 5: Scale Up and Integrate

- Expand the AI solution to other areas of your plant: Once you have proven the effectiveness of the AI solution in the pilot project, you can scale it up to other areas of your operation.

- Integrate with existing systems: Integrate the AI solution with your existing MES, ERP, and other systems to ensure seamless data flow and coordinated decision-making.

- Train your staff: Provide training to your staff on how to use the AI solution and interpret the data it provides.

Step 6: Continuous Improvement

- Continuously monitor and optimize the AI solution: AI is not a “set it and forget it” solution. It requires continuous monitoring and optimization to ensure that it is delivering the desired results.

- Stay up-to-date on the latest AI technology: AI technology is constantly evolving, so it’s important to stay up-to-date on the latest advancements.

- Seek feedback from your staff: Encourage your staff to provide feedback on the AI solution and how it can be improved.

Beyond Cost Savings: The Broader Benefits of AI-Driven Sustainability

While cost reduction is a primary driver for AI adoption in manufacturing, the benefits extend far beyond the financial realm. Embracing AI for energy efficiency unlocks a cascade of positive outcomes that enhance your company’s competitiveness, reputation, and long-term viability.

- Enhanced Sustainability: By reducing energy consumption and carbon emissions, AI helps manufacturers become more environmentally responsible and contribute to a more sustainable future. This is not just good for the planet; it’s good for business. Consumers are increasingly demanding environmentally friendly products and practices, and companies that embrace sustainability can gain a competitive advantage.

- Improved Operational Efficiency: AI optimizes manufacturing processes, reducing waste and improving overall efficiency. This leads to increased productivity, lower operating costs, and improved product quality. Think of it as a domino effect – one improvement leads to another.

- Enhanced Equipment Reliability: Predictive maintenance reduces downtime and extends the lifespan of equipment, saving money on repairs and replacements. This also improves safety by preventing unexpected equipment failures.

- Data-Driven Decision-Making: AI provides managers with real-time data insights that enable them to make informed decisions about energy management, production scheduling, and other critical areas. This empowers them to optimize operations and improve performance.

- Improved Employee Morale: Employees are more likely to be engaged and motivated when they work for a company that is committed to sustainability and innovation. AI can help create a more positive and productive work environment.

- Enhanced Brand Reputation: Companies that embrace AI for sustainability can enhance their brand reputation and attract environmentally conscious customers, investors, and employees. This can lead to increased sales, improved customer loyalty, and a stronger bottom line.

- Attracting and Retaining Talent: In today’s competitive job market, attracting and retaining top talent is crucial. A company with a commitment to sustainability and technological innovation, driven by AI, is more likely to attract the best and brightest minds.

Common Pitfalls to Avoid: Setting Yourself Up for AI Success

Implementing AI is not without its challenges. Avoiding these common pitfalls can significantly increase your chances of success:

- Lack of Clear Goals and Objectives: Without clear goals, it’s difficult to measure the success of the AI implementation and justify the investment.

- Poor Data Quality: AI algorithms are only as good as the data they are trained on. If the data is inaccurate or incomplete, the AI will produce unreliable results.

- Lack of Integration with Existing Systems: If the AI system is not integrated with existing systems, it will be difficult to share data and coordinate decision-making.

- Insufficient Training: Employees need to be trained on how to use the AI system and interpret the data it provides. Without proper training, they will not be able to effectively utilize the AI solution.

- Overlooking Cybersecurity: AI systems can be vulnerable to cyberattacks. It’s important to implement robust security measures to protect your data and prevent unauthorized access.

- Ignoring the Human Element: AI is a tool, not a replacement for human expertise. It’s important to involve employees in the AI implementation process and ensure that they understand the benefits of AI.

- Expecting Instant Results: AI implementation takes time and effort. Don’t expect to see immediate results. It’s important to be patient and persistent.

The Future is Intelligent: AI’s Evolving Role in Sustainable Manufacturing

The integration of AI in manufacturing is not just a trend; it’s a fundamental shift toward smarter, more sustainable operations. As AI technology continues to evolve, its role in driving energy efficiency and promoting sustainability will only become more prominent. We are on the cusp of a new era of manufacturing, one where AI-powered insights and automation are the norm, not the exception.

Here’s a glimpse into the future:

- More Sophisticated AI Algorithms: Future AI algorithms will be even more powerful and capable of handling complex data and optimizing processes in real-time.

- Increased Use of Edge Computing: Edge computing will enable AI algorithms to be deployed closer to the source of data, reducing latency and improving responsiveness.

- Greater Integration of AI with IoT: The Internet of Things (IoT) will provide a vast network of sensors and devices that can collect data on energy consumption and machine performance, providing AI algorithms with even more information to work with.

- AI-Powered Digital Twins: Digital twins, virtual representations of physical assets, will be used to simulate different scenarios and optimize energy consumption before implementing changes in the real world.

- Autonomous Manufacturing: AI will enable more autonomous manufacturing processes, reducing the need for human intervention and minimizing energy waste.

- Focus on Circular Economy: AI will play a crucial role in promoting a circular economy by optimizing resource utilization, reducing waste, and enabling the reuse and recycling of materials.

The journey to AI-powered energy efficiency in manufacturing is a continuous one. By embracing this technology and investing in the necessary skills and infrastructure, manufacturers can unlock significant cost savings, reduce their environmental impact, and build a more sustainable future.

Need Help Navigating the AI Landscape? Let the Experts Guide You.

The path to AI implementation can feel overwhelming. Knowing where to start, which technologies to choose, and how to integrate them effectively requires specialized expertise. That’s where AI Business Consultancy comes in.

At AI Business Consultancy (https://ai-business-consultancy.com/), we are dedicated to helping businesses harness the power of AI to achieve their strategic goals. Our team of experienced AI consultants provides comprehensive AI consultancy services, guiding you through every step of the AI adoption process, from initial assessment to implementation and ongoing optimization.

Here’s how we can help:

- AI Strategy Development: We work with you to develop a tailored AI strategy that aligns with your business objectives and addresses your specific challenges.

- AI Solution Selection: We help you identify the right AI solutions for your needs, based on a thorough assessment of your requirements and a deep understanding of the AI landscape.

- AI Implementation Support: We provide hands-on support during the AI implementation process, ensuring a smooth and successful deployment.

- AI Training and Education: We offer training and education programs to empower your staff to effectively utilize AI solutions and interpret the data they provide.

- AI Optimization and Continuous Improvement: We provide ongoing support to optimize your AI solutions and ensure that they continue to deliver value over time.

Why Choose AI Business Consultancy?

- Deep Expertise: Our team comprises experienced AI consultants with a proven track record of success in helping businesses implement AI solutions.

- Tailored Solutions: We understand that every business is unique. We provide tailored solutions that are designed to meet your specific needs.

- Results-Oriented Approach: We are committed to delivering measurable results and helping you achieve your business objectives.

- Collaborative Partnership: We work closely with you as a trusted partner, providing ongoing support and guidance throughout the AI adoption process.

Don’t let the complexities of AI hold you back. Contact AI Business Consultancy (https://ai-business-consultancy.com/) today to learn how we can help you unlock the power of AI and transform your business. Let us help you navigate the AI landscape and achieve your strategic goals.

Leave a Reply