The Silent Thief: Understanding Corrosion in the Marine World

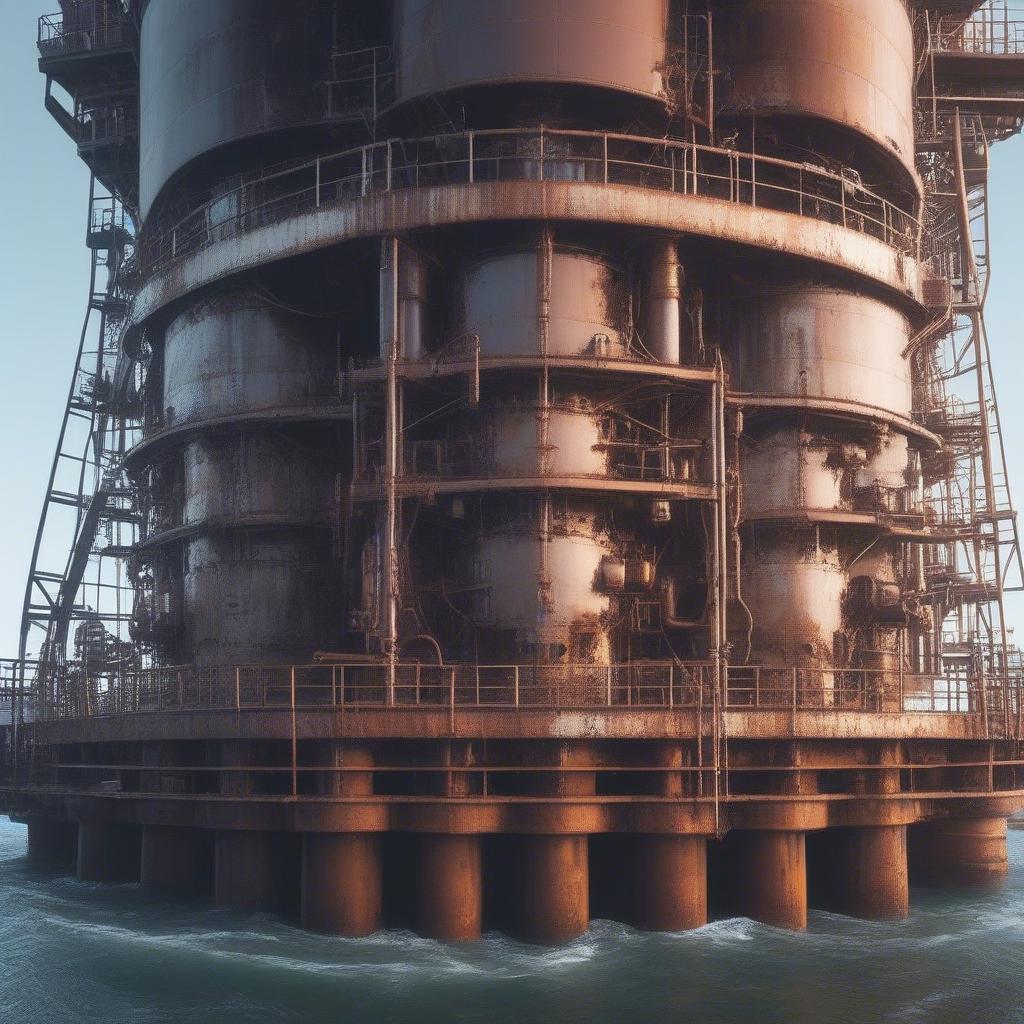

Corrosion. The very word sends shivers down the spines of marine engineers, ship owners, and anyone involved in the maritime industry. It’s the relentless enemy, gnawing away at everything from massive cargo ships to intricate underwater pipelines. But what exactly is it, and why is it such a pervasive problem in the marine environment?

At its core, corrosion is a natural process where a refined metal is converted to a more chemically stable form, such as its oxide, hydroxide, or sulfide. Think of rust on iron – that reddish-brown flaky stuff is iron oxide, the result of iron reacting with oxygen and water. In the marine environment, the process is accelerated due to the presence of:

- Saltwater: Saltwater is a highly conductive electrolyte, speeding up electrochemical reactions that cause corrosion.

- Dissolved Oxygen: Oxygen is a key ingredient in many corrosion reactions.

- Temperature Variations: Fluctuations in temperature can influence the rate of corrosion.

- Marine Organisms: Biofouling, the accumulation of marine organisms on surfaces, can create corrosive microenvironments.

- Mechanical Stress: The constant pounding of waves and the movement of vessels create stress points that are more susceptible to corrosion.

The consequences of unchecked corrosion can be catastrophic, leading to:

- Structural Failure: Weakened hulls, damaged pipelines, and compromised equipment can lead to accidents and environmental disasters.

- Operational Inefficiency: Corroded components can reduce the performance of machinery and increase fuel consumption.

- Increased Maintenance Costs: Repairing or replacing corroded parts is expensive and time-consuming.

- Safety Hazards: Corrosion can compromise the safety of personnel and the integrity of operations.

Keywords: corrosion detection tools, marine maintenance ai

Why Traditional Corrosion Management Falls Short

For decades, the marine industry has relied on traditional methods to combat corrosion, including:

- Protective Coatings: Applying paints, coatings, and linings to create a barrier between the metal and the corrosive environment.

- Cathodic Protection: Using sacrificial anodes or impressed current systems to make the metal structure the cathode in an electrochemical cell, thus preventing corrosion.

- Material Selection: Choosing corrosion-resistant materials, such as stainless steel or aluminum alloys, for critical components.

- Regular Inspections: Conducting visual inspections and non-destructive testing (NDT) to identify corrosion damage.

While these methods are essential, they have limitations:

- Reactive Approach: Inspections often detect corrosion after it has already started, leading to reactive repairs rather than proactive prevention.

- Subjectivity: Visual inspections are subjective and can be influenced by the experience and training of the inspector.

- Limited Accessibility: Some areas, such as underwater pipelines or the inside of ballast tanks, are difficult to inspect.

- Costly and Time-Consuming: Regular inspections and maintenance can be expensive and disruptive to operations.

- Inaccurate Prediction: Predicting the future corrosion rate and remaining useful life of equipment is challenging.

Keywords: marine maintenance ai, corrosion detection tools

AI to the Rescue: Revolutionizing Corrosion Prediction

Enter Artificial Intelligence (AI). AI offers a paradigm shift in how we approach corrosion management in the marine industry. Instead of reacting to corrosion damage, AI enables predictive maintenance, allowing us to anticipate problems before they occur.

Here’s how AI is transforming the landscape:

-

Data-Driven Insights: AI algorithms can analyze vast amounts of data from various sources, including:

- Sensor Data: Data from corrosion sensors, temperature sensors, humidity sensors, and pressure sensors.

- Inspection Reports: Historical inspection data, including visual inspection reports, NDT results, and repair records.

- Environmental Data: Weather data, sea state data, and water quality data.

- Operational Data: Vessel operating parameters, such as speed, route, and cargo.

- Material Data: Material composition, coating type, and cathodic protection system parameters.

-

Predictive Modeling: By analyzing this data, AI algorithms can build predictive models that forecast the future corrosion rate and remaining useful life of equipment.

-

Early Warning System: AI can identify early warning signs of corrosion, allowing for proactive maintenance interventions.

-

Optimized Maintenance Schedules: AI can optimize maintenance schedules based on predicted corrosion rates, minimizing downtime and reducing costs.

-

Improved Safety: By preventing corrosion-related failures, AI enhances the safety of personnel and operations.

Keywords: marine maintenance ai, corrosion detection tools, shipyard automation

The Power of Machine Learning: Understanding the Algorithms

At the heart of AI-powered corrosion prediction lies machine learning (ML). ML algorithms are trained on historical data to identify patterns and relationships that are not readily apparent to humans. Several ML algorithms are particularly well-suited for corrosion prediction:

-

Regression Models: These models predict a continuous variable, such as the corrosion rate or remaining useful life. Common regression algorithms include:

- Linear Regression: A simple algorithm that models the relationship between variables as a straight line.

- Polynomial Regression: A more complex algorithm that models the relationship between variables as a curve.

- Support Vector Regression (SVR): A powerful algorithm that can handle non-linear relationships between variables.

- Random Forest Regression: An ensemble learning method that combines multiple decision trees to improve prediction accuracy.

-

Classification Models: These models predict a categorical variable, such as the presence or absence of corrosion. Common classification algorithms include:

- Logistic Regression: A statistical model that predicts the probability of a binary outcome.

- Support Vector Machines (SVM): A powerful algorithm that can classify data into different categories.

- Decision Trees: A tree-like structure that represents a series of decisions to classify data.

- Random Forest Classification: An ensemble learning method that combines multiple decision trees to improve classification accuracy.

-

Neural Networks: These are complex algorithms inspired by the structure of the human brain. They can learn intricate patterns from data and are particularly well-suited for predicting complex phenomena like corrosion. Types of neural networks used in corrosion prediction include:

- Artificial Neural Networks (ANNs): General-purpose neural networks that can be used for both regression and classification tasks.

- Convolutional Neural Networks (CNNs): Specifically designed for processing images and can be used to analyze images of corroded surfaces.

- Recurrent Neural Networks (RNNs): Designed for processing sequential data, such as time-series data from corrosion sensors.

Keywords: marine maintenance ai

Practical Applications: Real-World Examples of AI in Action

AI is no longer just a theoretical concept. It’s being implemented in real-world marine applications, delivering tangible benefits. Here are some examples:

-

Predicting Corrosion in Ship Hulls: AI algorithms are being used to analyze sensor data, inspection reports, and environmental data to predict corrosion rates in ship hulls. This allows ship owners to schedule maintenance proactively, preventing costly repairs and downtime.

- Example: A shipping company uses AI to predict corrosion in the ballast tanks of its cargo ships. By analyzing historical inspection data and sensor data, the AI identifies areas that are at high risk of corrosion. The company then focuses its maintenance efforts on these areas, preventing structural failures and extending the lifespan of its vessels.

-

Monitoring Corrosion in Offshore Pipelines: AI is being used to monitor corrosion in offshore pipelines, ensuring the safe and reliable transport of oil and gas. AI algorithms analyze data from corrosion sensors and inspection reports to detect early warning signs of corrosion and predict the remaining useful life of the pipelines.

- Example: An oil and gas company uses AI to monitor corrosion in its subsea pipelines. By analyzing data from ultrasonic sensors and electrochemical sensors, the AI detects areas where corrosion is accelerating. The company then deploys remotely operated vehicles (ROVs) to inspect these areas and perform necessary repairs, preventing leaks and environmental damage.

-

Optimizing Cathodic Protection Systems: AI can optimize the performance of cathodic protection systems by analyzing data from sensors and adjusting the current output to minimize corrosion rates.

- Example: A port authority uses AI to optimize the cathodic protection system for its marine infrastructure. By analyzing data from reference electrodes and current sensors, the AI adjusts the current output of the cathodic protection system to ensure that all structures are adequately protected from corrosion.

-

Automating Corrosion Inspection: AI-powered robots and drones are being used to automate corrosion inspection, reducing the need for human inspectors and improving the accuracy and efficiency of inspections.

- Example: A shipyard uses AI-powered drones to inspect the hulls of ships for corrosion. The drones are equipped with high-resolution cameras and sensors that can detect even small signs of corrosion. The AI analyzes the images and sensor data to identify areas that require further inspection and repair. (Keyword: Shipyard Automation)

-

Material Selection Optimization: AI can analyze the performance of different materials in specific marine environments, enabling engineers to select the most corrosion-resistant materials for new construction and repairs.

- Example: A marine construction company uses AI to select the best materials for a new pier. The AI analyzes historical data on the performance of different materials in the local marine environment, taking into account factors such as salinity, temperature, and wave action. The company then uses this information to select materials that will provide the longest possible service life.

Keywords: shipyard automation, corrosion detection tools, marine maintenance ai

Implementing AI for Corrosion Prediction: A Step-by-Step Guide

Implementing AI for corrosion prediction is a complex process, but it can be broken down into several key steps:

-

Define the Problem: Clearly define the specific corrosion problem you want to address with AI. What equipment or structures are you concerned about? What data do you have available? What are your goals for AI implementation?

- Example: “We want to use AI to predict corrosion in the hulls of our cargo ships to reduce maintenance costs and prevent structural failures.”

-

Gather Data: Collect as much relevant data as possible, including sensor data, inspection reports, environmental data, operational data, and material data. Ensure that the data is accurate, complete, and well-organized.

- Example: “We have historical inspection reports, sensor data from cathodic protection systems, weather data, and vessel operating data.”

-

Prepare Data: Clean and preprocess the data to remove errors, inconsistencies, and missing values. Transform the data into a format that can be used by machine learning algorithms. This may involve:

- Data Cleaning: Removing or correcting errors and inconsistencies in the data.

- Data Transformation: Converting data into a suitable format for machine learning algorithms.

- Feature Engineering: Creating new features from existing data to improve the performance of the AI model.

- Example: “We need to clean the inspection reports to remove inconsistencies in the data and transform the sensor data into a time-series format.”

-

Select an AI Algorithm: Choose the appropriate machine learning algorithm based on the type of data you have and the type of prediction you want to make. Consider factors such as the complexity of the problem, the size of the dataset, and the desired accuracy.

- Example: “We will use a recurrent neural network (RNN) to predict corrosion rates based on time-series sensor data.”

-

Train the AI Model: Train the AI model using the historical data. This involves feeding the data into the algorithm and adjusting its parameters until it can accurately predict corrosion rates.

- Example: “We will train the RNN on historical sensor data and inspection reports to predict future corrosion rates.”

-

Validate the AI Model: Validate the AI model using a separate dataset that was not used for training. This will ensure that the model is accurate and reliable.

- Example: “We will validate the RNN using data from a different set of ships to ensure that it generalizes well to new vessels.”

-

Deploy the AI Model: Deploy the AI model into a production environment where it can be used to predict corrosion rates in real-time.

- Example: “We will deploy the RNN into a cloud-based platform that can continuously monitor sensor data and predict corrosion rates.”

-

Monitor and Maintain the AI Model: Continuously monitor the performance of the AI model and retrain it as needed to maintain its accuracy and reliability. As new data becomes available, use it to refine the model and improve its predictive capabilities.

- Example: “We will continuously monitor the RNN’s predictions and retrain it with new data to improve its accuracy over time.”

Keywords: marine maintenance ai, corrosion detection tools

Overcoming the Challenges: Addressing Common Hurdles

Implementing AI for corrosion prediction is not without its challenges. Some common hurdles include:

- Data Availability and Quality: Lack of sufficient and high-quality data can limit the accuracy of AI models.

- Solution: Invest in collecting and managing data more effectively. Implement sensor networks, standardize inspection procedures, and create a centralized data repository.

- Expertise and Skills: Developing and deploying AI models requires specialized expertise in data science, machine learning, and corrosion engineering.

- Solution: Partner with AI experts or invest in training programs for your existing staff.

- Integration with Existing Systems: Integrating AI models with existing maintenance management systems and workflows can be complex.

- Solution: Choose AI solutions that are compatible with your existing systems and work with experienced integration partners.

- Trust and Acceptance: Building trust in AI predictions and gaining acceptance from stakeholders can be challenging.

- Solution: Communicate clearly about the capabilities and limitations of AI, involve stakeholders in the implementation process, and demonstrate the value of AI through pilot projects.

- Cost: Implementing AI solutions can be expensive, requiring investments in hardware, software, and expertise.

- Solution: Start with a small-scale pilot project to demonstrate the value of AI before making a larger investment.

Keywords: marine maintenance ai

The Future of Corrosion Prediction: Emerging Trends and Technologies

The field of AI-powered corrosion prediction is constantly evolving. Some emerging trends and technologies include:

- Digital Twins: Creating virtual replicas of physical assets that can be used to simulate corrosion and test different maintenance strategies.

- Edge Computing: Deploying AI models on edge devices, such as sensors and drones, to enable real-time corrosion detection and analysis.

- Explainable AI (XAI): Developing AI models that can explain their predictions, making it easier for humans to understand and trust the results.

- Generative AI: Using generative AI models to create synthetic data for training AI models when real-world data is scarce. This can be particularly useful for simulating rare or extreme corrosion scenarios.

These advancements promise to further enhance the accuracy, efficiency, and effectiveness of AI-powered corrosion prediction in the marine industry.

Keywords: marine maintenance ai, shipyard automation

Case Studies: Success Stories of AI in Marine Corrosion Management

Several companies and organizations have already achieved significant success by implementing AI for corrosion management in the marine industry. Here are a few brief examples:

- Company A: A major shipping company reduced its maintenance costs by 15% by using AI to predict corrosion in its fleet of cargo ships. The AI model identified areas that were at high risk of corrosion, allowing the company to focus its maintenance efforts on these areas and prevent costly repairs.

- Organization B: A port authority improved the safety and reliability of its marine infrastructure by using AI to monitor corrosion in its piers and docks. The AI model detected early warning signs of corrosion, allowing the authority to take proactive measures to prevent structural failures.

- Company C: An oil and gas company reduced the risk of pipeline leaks by using AI to monitor corrosion in its subsea pipelines. The AI model analyzed data from corrosion sensors and inspection reports to detect areas where corrosion was accelerating.

These case studies demonstrate the tangible benefits of AI-powered corrosion management in the marine industry.

Keywords: marine maintenance ai

Choosing the Right AI Solution: Considerations for Marine Businesses

Selecting the right AI solution for corrosion prediction requires careful consideration of several factors:

- Specific Needs: Identify your specific needs and goals for AI implementation. What equipment or structures are you concerned about? What data do you have available? What are your desired outcomes?

- Data Availability and Quality: Assess the availability and quality of your data. Do you have sufficient and high-quality data to train an AI model? If not, you may need to invest in collecting more data.

- Technical Expertise: Evaluate your in-house technical expertise. Do you have the skills and resources to develop and deploy AI models? If not, you may need to partner with an AI expert.

- Integration Capabilities: Consider the integration capabilities of the AI solution. Can it be easily integrated with your existing maintenance management systems and workflows?

- Cost: Compare the costs of different AI solutions. Consider the upfront costs, ongoing maintenance costs, and potential return on investment.

- Vendor Reputation and Support: Research the reputation and support capabilities of different AI vendors. Choose a vendor with a proven track record and a strong commitment to customer support.

By carefully considering these factors, you can select an AI solution that is well-suited to your specific needs and goals.

Keywords: marine maintenance ai

The Role of AI Business Consultancy (https://ai-business-consultancy.com/)

Navigating the complex world of AI can be daunting. That’s where AI Business Consultancy comes in. We help marine businesses like yours leverage the power of AI to optimize corrosion management and achieve significant cost savings, improved safety, and enhanced operational efficiency.

Our team of experienced AI consultants provides a range of services, including:

- AI Strategy Development: We work with you to develop a customized AI strategy that aligns with your specific business goals and objectives.

- Data Assessment and Preparation: We assess the quality and availability of your data and help you prepare it for AI modeling.

- AI Model Selection and Development: We help you select the appropriate AI algorithms for your specific needs and develop customized AI models that are tailored to your data.

- AI Implementation and Integration: We help you implement and integrate AI models with your existing maintenance management systems and workflows.

- Training and Support: We provide training and support to your staff to ensure that they can effectively use and maintain the AI models.

We understand the unique challenges faced by marine businesses and are committed to providing customized AI solutions that deliver tangible results. Visit our website at https://ai-business-consultancy.com/ to learn more about our services and how we can help you harness the power of AI for corrosion management.

Conclusion: Embracing the AI Revolution for a Corrosion-Free Future

Corrosion is a persistent and costly problem in the marine industry. But with the advent of AI, we now have the tools to predict, prevent, and mitigate corrosion damage more effectively than ever before. By embracing the AI revolution, marine businesses can unlock significant cost savings, improve safety, and enhance operational efficiency. The future of corrosion management is here, and it’s powered by AI. Keywords: marine maintenance ai, corrosion detection tools, shipyard automation

Leave a Reply